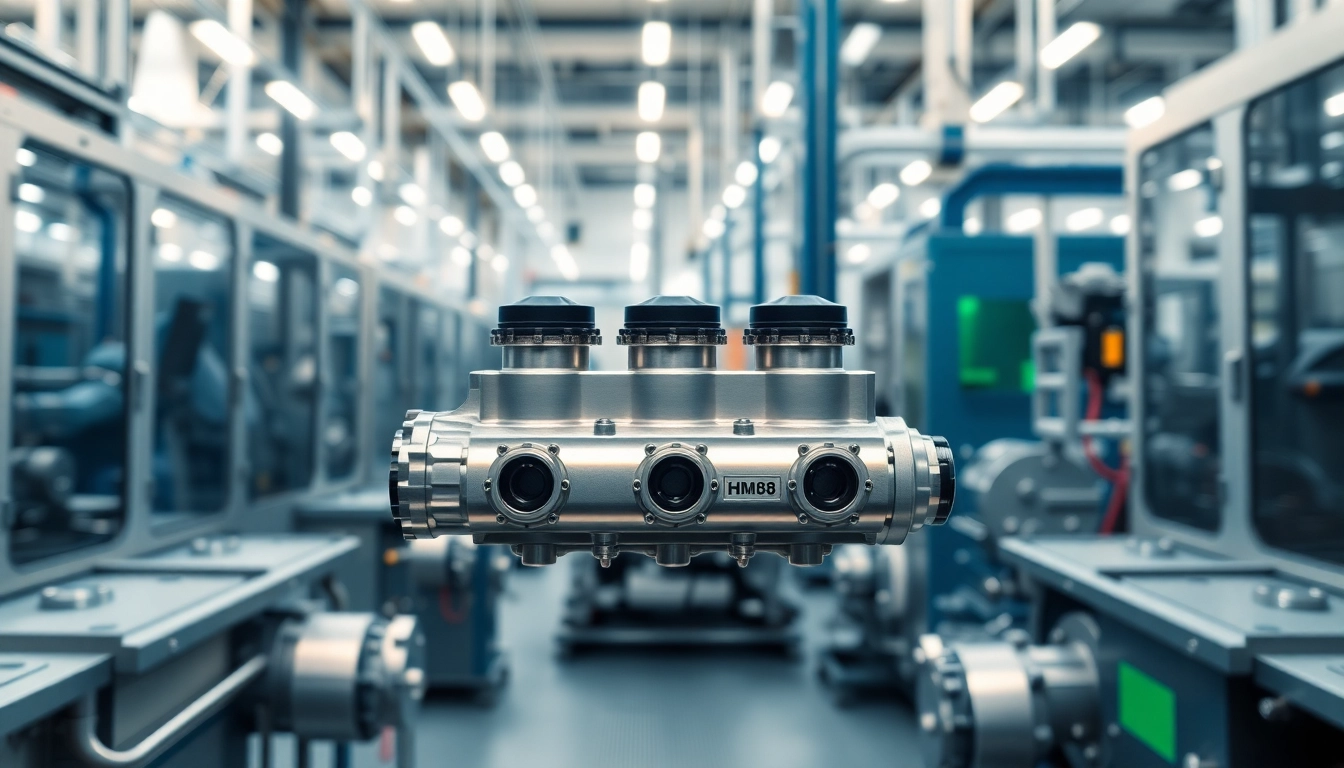

Understanding the HM88 Series: Key Features and Benefits

The HM88 series stands as a pivotal advancement in manifold technology, equipped with unique features designed for exceptional functionality in various industrial applications. With its robust design and innovative engineering, the HM88 series addresses numerous challenges faced by engineers and operators. When exploring options, hm88 provides comprehensive insights that can guide your decision-making process in selecting the right manifold solution.

Overview of the HM88 Series Manifold

The HM88 series manifolds are engineered to facilitate accurate and reliable fluid control. Key features include:

- Three-Valve Direct Mount Design: This configuration allows for seamless integration with differential pressure transmitters, minimizing installation space and improving response times.

- High-Quality Materials: The use of corrosion-resistant alloys ensures longevity and withstands extreme operating conditions, making them ideal for harsh environments.

- Easy Maintenance: The design enables straightforward maintenance procedures, reducing downtime and operational costs.

Advantages of Using Three-Valve Direct Mount Systems

The use of three-valve direct mount systems, such as those seen in the HM88 series, offers several advantages:

- Enhanced Accuracy: Direct mounting reduces the number of connection points, thereby minimizing potential leak points and enhancing measurement accuracy.

- Space-Saving Configuration: These systems are designed to occupy minimal space, making them suitable for installations with limited room.

- Quick Installation: The straightforward design allows for faster installation times, which is crucial for tight project schedules.

Applications in Various Industries

The HM88 series manifolds find applications across numerous sectors, including:

- Oil and Gas: Used for pressure monitoring and control in upstream and downstream applications.

- Water Treatment: Ideal for managing pressure in filtration systems and treatment plants.

- Pharmaceuticals: Ensures precise control of processes where accuracy is critical.

Installation Best Practices for HM88 Series Manifolds

Successful installation of HM88 series manifolds involves careful attention to detail and adherence to best practices. This ensures optimal performance and longevity of the equipment.

Step-by-Step Installation Guide

Follow these steps to install the HM88 series manifold:

- Preparation: Check the installation site for compatibility with the manifold specifications.

- Secure Mounting: Ensure that the manifold is mounted securely using recommended hardware to prevent vibration and displacement.

- Connect Pipelines: Properly connect the inlet and outlet pipelines while ensuring that seals are intact to prevent leaks.

- Pressure Testing: Conduct pressure tests to verify the integrity of the installation before commissioning.

Common Installation Challenges and Solutions

While installing the HM88 series manifolds, you might encounter challenges such as:

- Piping Alignment Issues: Ensure all pipes are properly aligned before securing connections to avoid undue stress on the manifold.

- Leakages: Utilize high-quality seals and conduct thorough checks post-installation to prevent any leaks.

Tools and Materials Needed

Gather the following tools and materials before starting the installation:

- Wrenches and sockets

- Sealants (as required)

- Torque wrench for secure fittings

- Pressure testing equipment

Maintenance and Trouble-Shooting for Optimal Performance

Ongoing maintenance is crucial to ensure the HM88 series manifold operates effectively and efficiently throughout its lifecycle.

Routine Maintenance Checks for the HM88 Series

Perform the following maintenance checks regularly:

- Visual Inspections: Look for signs of wear, corrosion, and leaks.

- Pressure Calibration: Verify pressure readings with calibrated tools to ensure accuracy.

- Seal Integrity: Check seals and gaskets for deterioration and replace them as needed.

Troubleshooting Common Issues

If performance issues arise, consider these troubleshooting steps:

- Check for Blockages: Inspect pipelines for any obstructions that could affect flow rates.

- Examine Valves: Ensure that all valves are functioning correctly and free from dirt or debris.

When to Seek Professional Help

If you encounter persistent issues that cannot be resolved through standard troubleshooting methods, it may be time to contact a professional. Their expertise can help prevent further damage and ensure compliance with safety regulations.

Performance Metrics: Measuring Success with HM88

To assess the effectiveness of the HM88 series manifolds, it is important to monitor key performance metrics regularly.

Key Performance Indicators (KPIs) to Monitor

Some relevant KPIs for the HM88 series include:

- Flow Rate: Measure the flow rate to ensure it meets operational specifications.

- Pressure Drop: Monitor pressure drops to identify potential blockages or inefficiencies.

- Maintenance Frequency: Track how often maintenance is performed to determine if adjustments are needed.

Case Studies: Success Stories with HM88 Series

Several companies have reported significant improvements after implementing the HM88 series manifolds in their operations:

- Energy Sector: A leading oil company improved pressure control efficiency by 30% after switching to HM88 series systems.

- Water Utilities: A municipal water treatment facility reduced downtime by 25% due to the ease of maintenance offered by the HM88 manifold design.

Impact on Efficiency and Productivity

The introduction of the HM88 series significantly boosts operational efficiency, leading to increased productivity across various industries. By minimizing downtime and improving measurement accuracy, companies can enhance their overall performance.

Future Trends in Manifold Technology: Looking Ahead to 2025

The manifold technology landscape is evolving, presenting numerous opportunities for advancements that will benefit industries reliant on reliable fluid control systems.

Emerging Technologies in the Industry

New developments in sensor technology, automation, and remote monitoring are set to transform the manifold sector. These innovations will facilitate real-time data collection and analysis, enabling predictive maintenance and improved decision-making.

Innovations in Manifold Systems

Future iterations of manifold systems, such as the HM88 series, are expected to integrate advanced materials that enhance durability while reducing weight. Furthermore, connectivity features will allow for better integration into smart manufacturing environments, ensuring seamless operational continuity.

Predictions for HM88 in the Next Five Years

As we look to 2025, the HM88 series is poised to remain at the forefront of manifold solutions. Anticipated features include enhanced compatibility with IoT systems, improved energy efficiency, and innovative designs that prioritize sustainability. With emerging trends paving the way, HM88 will lead the charge in providing solutions that meet not only current needs but also future demands of industry.